Printing arm

Commissioned in November 2018 at a total cost of $300k, a 280 sq. ft. enclosure providing atmospheric isolation was outfitted with an ABB Robotics IRB 6700 series, 7th generation, high payload, high performance industrial robot. The robot has a large working range of 2.85 meters, high wrist torque, and high production capacity. Coupled with 6-axes of rotation, this allows for a large range of configurations and seamless transition between points in space. The robot has been adapted with a variable temperature melt extruder to produce sulfur-based concretes for both Earth and Mars constructions. Due to the open nature of the extruder, the robot is also capable of printing with various other temperature-dependent composites. To allow the greatest freedom of programming and research, the robot has been set up for control via both ABB Robot Studio tooling software, as is standard in manufacturing industry, and RoboDK software, which allows Python interfacing and a high degree of functional freedom.

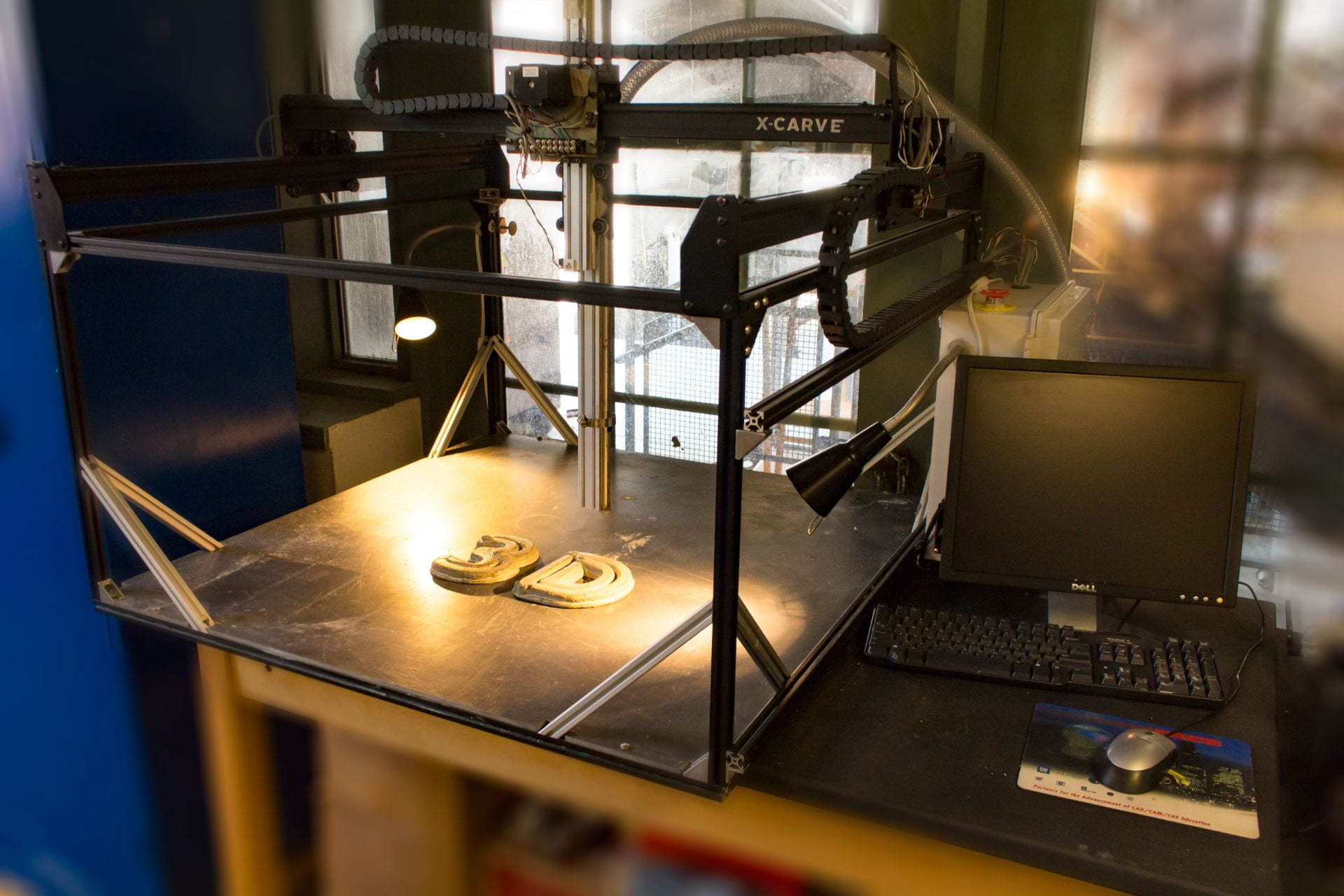

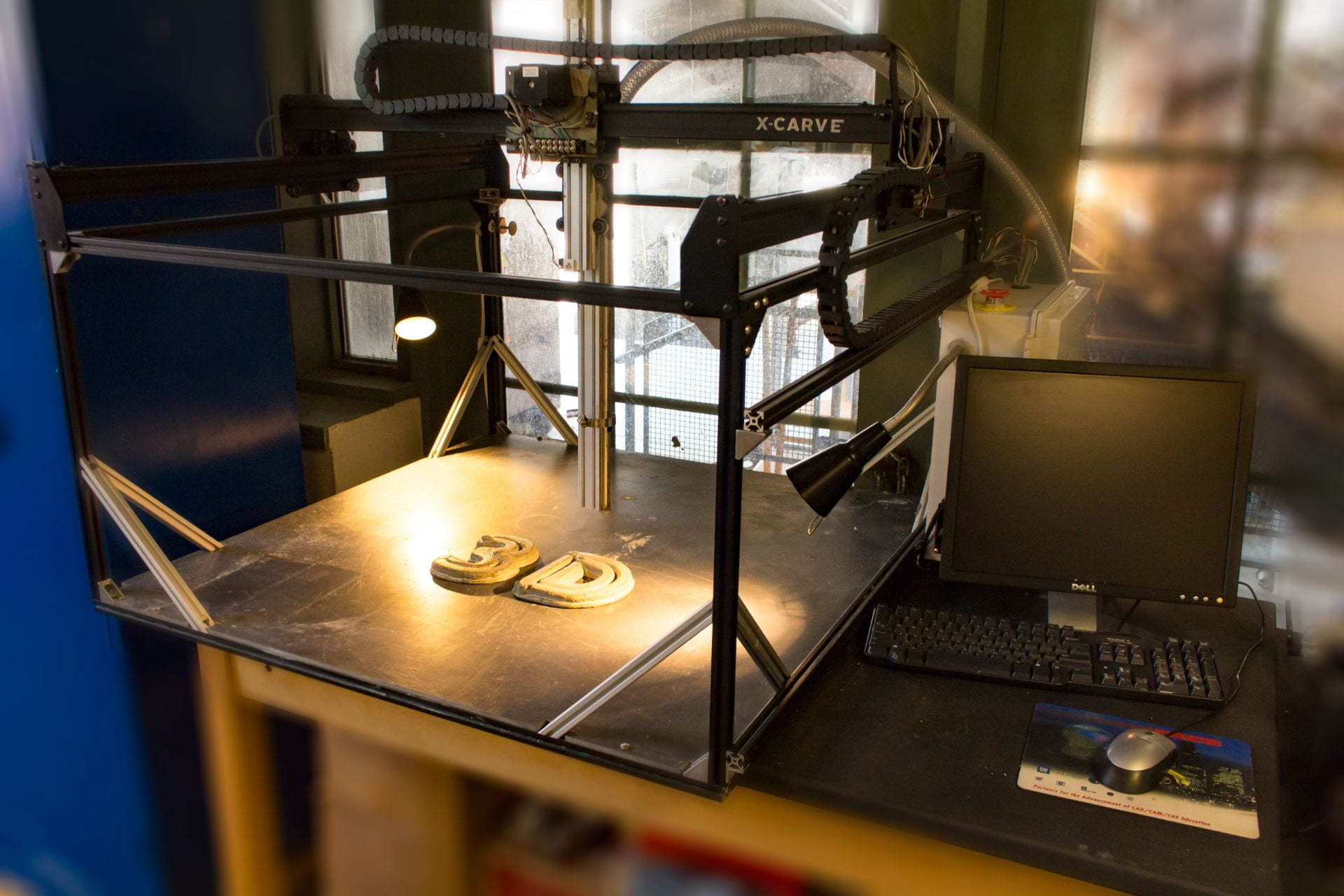

Small scale concrete printer

Northwestern’s cement 3D printer provides a unique research opportunity into rheological behavior of printed cementitious pastes. The printer utilizes a modified CNC machine frame to act as the gantry, and pressurizes the paste using a Liberty Process Equipment progressive cavity pump and high torque stepper motor. The printer is controlled via mirco controllers and Repetier-Host, a highly flexible open software package.

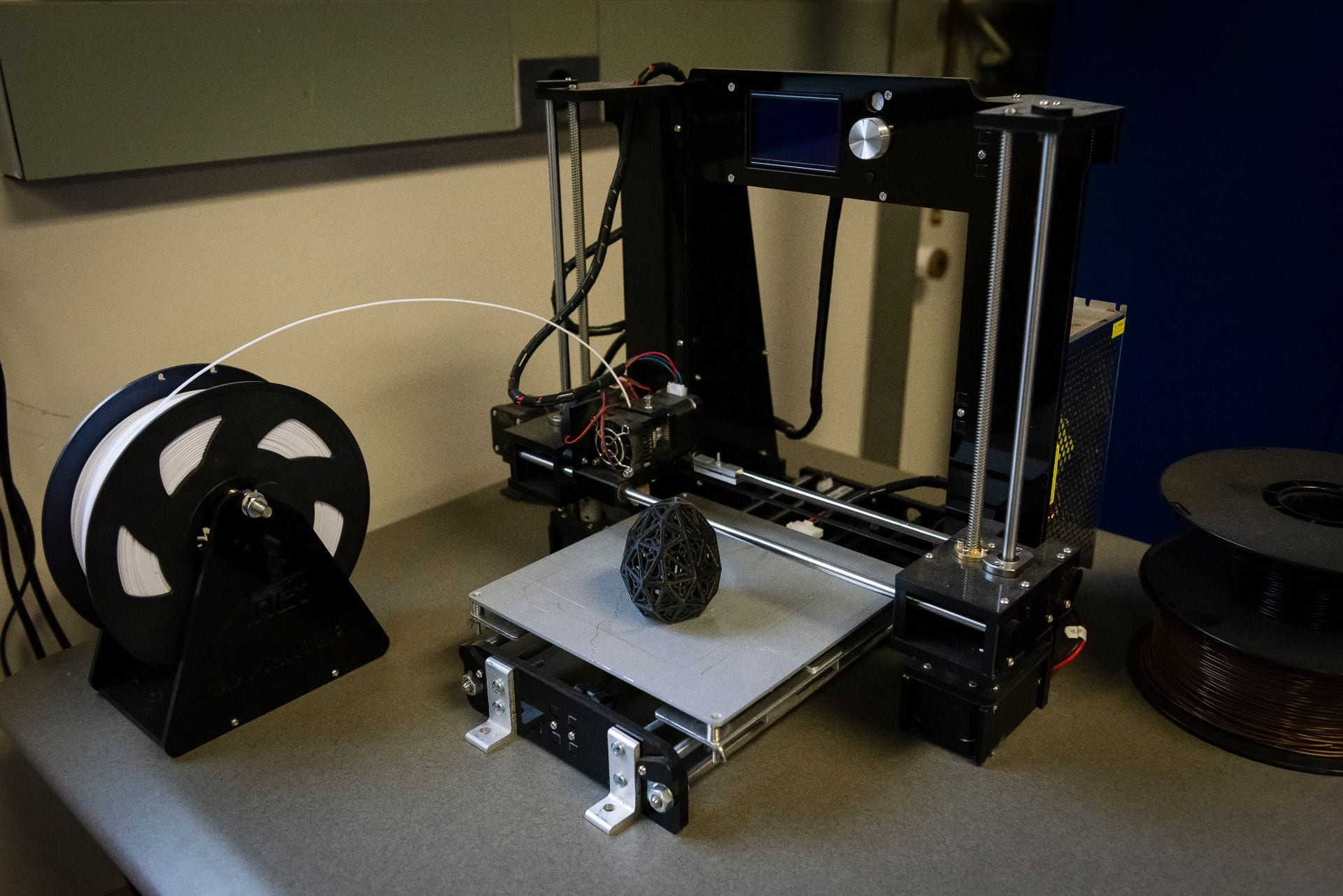

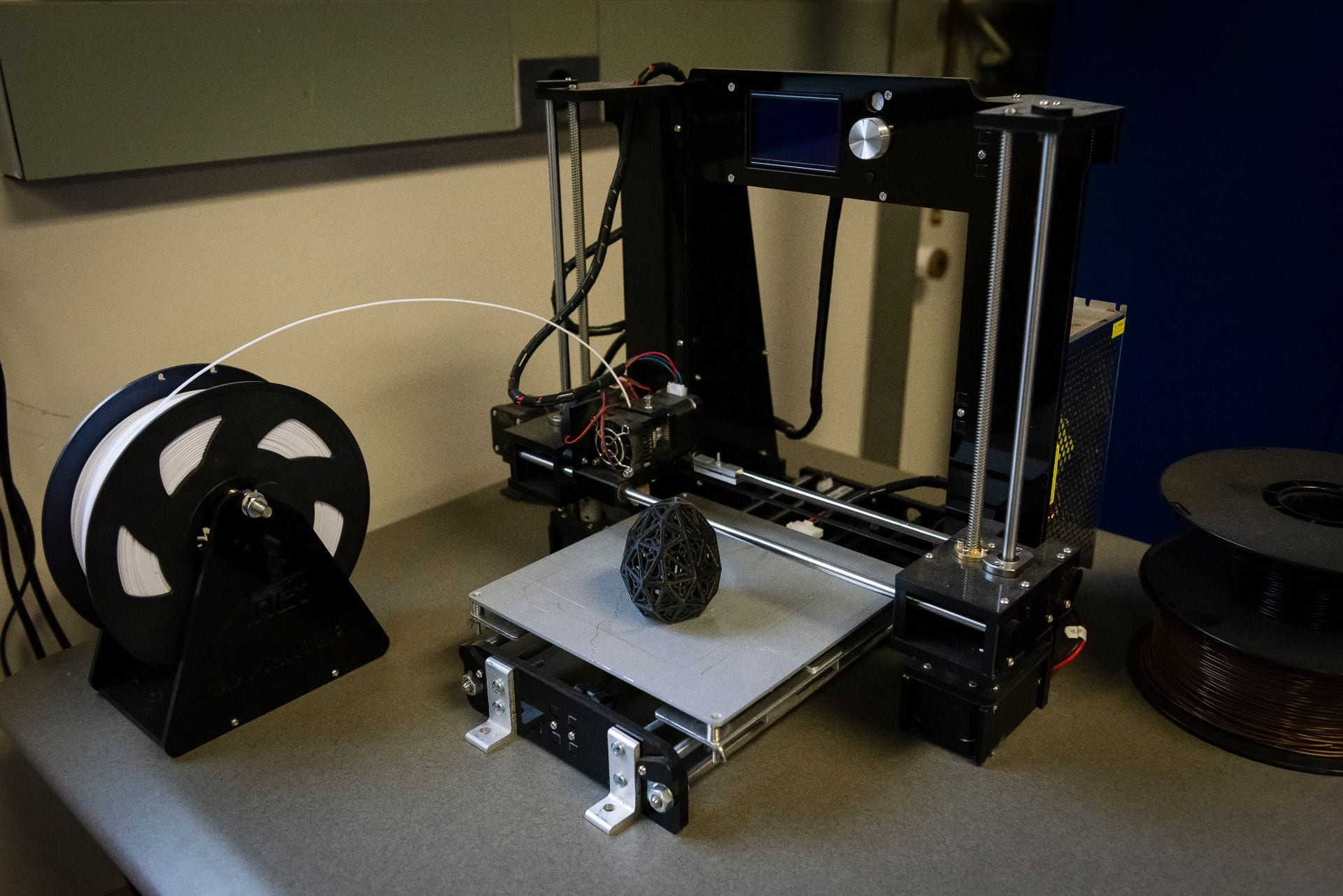

Plastic printer

The Multi-Scale 3D Printing Infrastructure Laboratory also hosts an Anet A6 plastics 3D printer for developing mockups and equipment parts. The printer is capable of printing with Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), High Impact Polystyrene (HIPS), and several other plastic filaments.

Robotic arm & fluidized bed apparatus

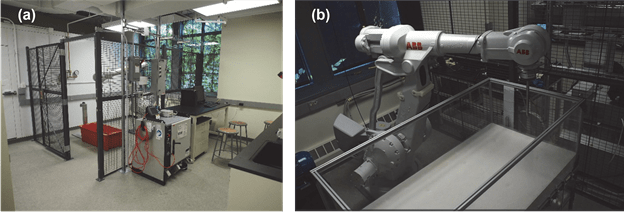

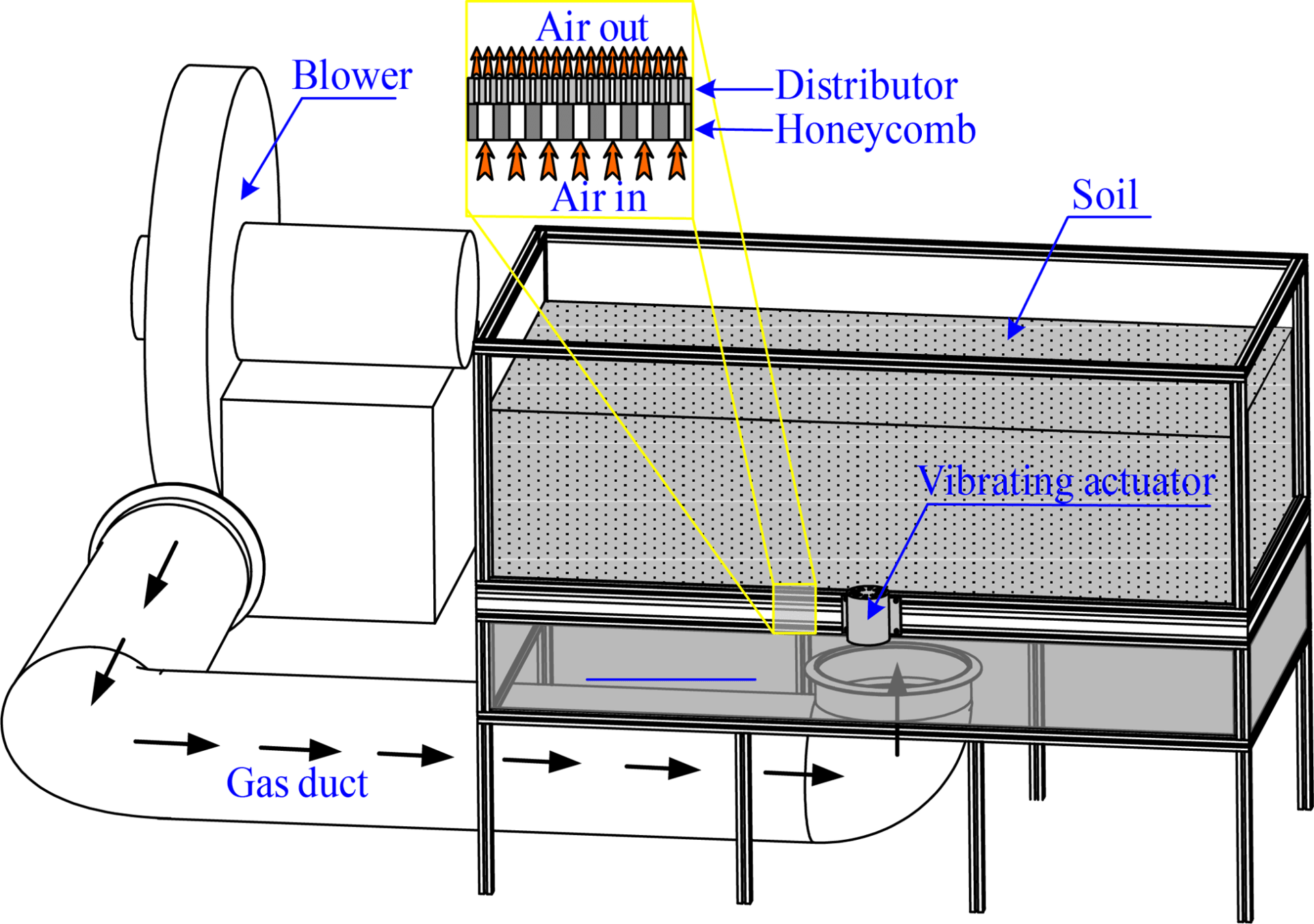

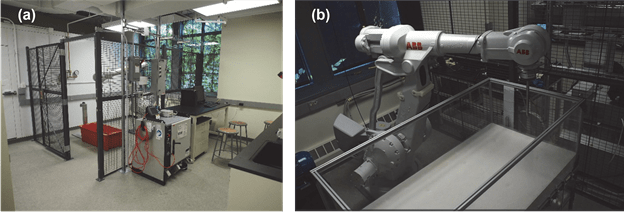

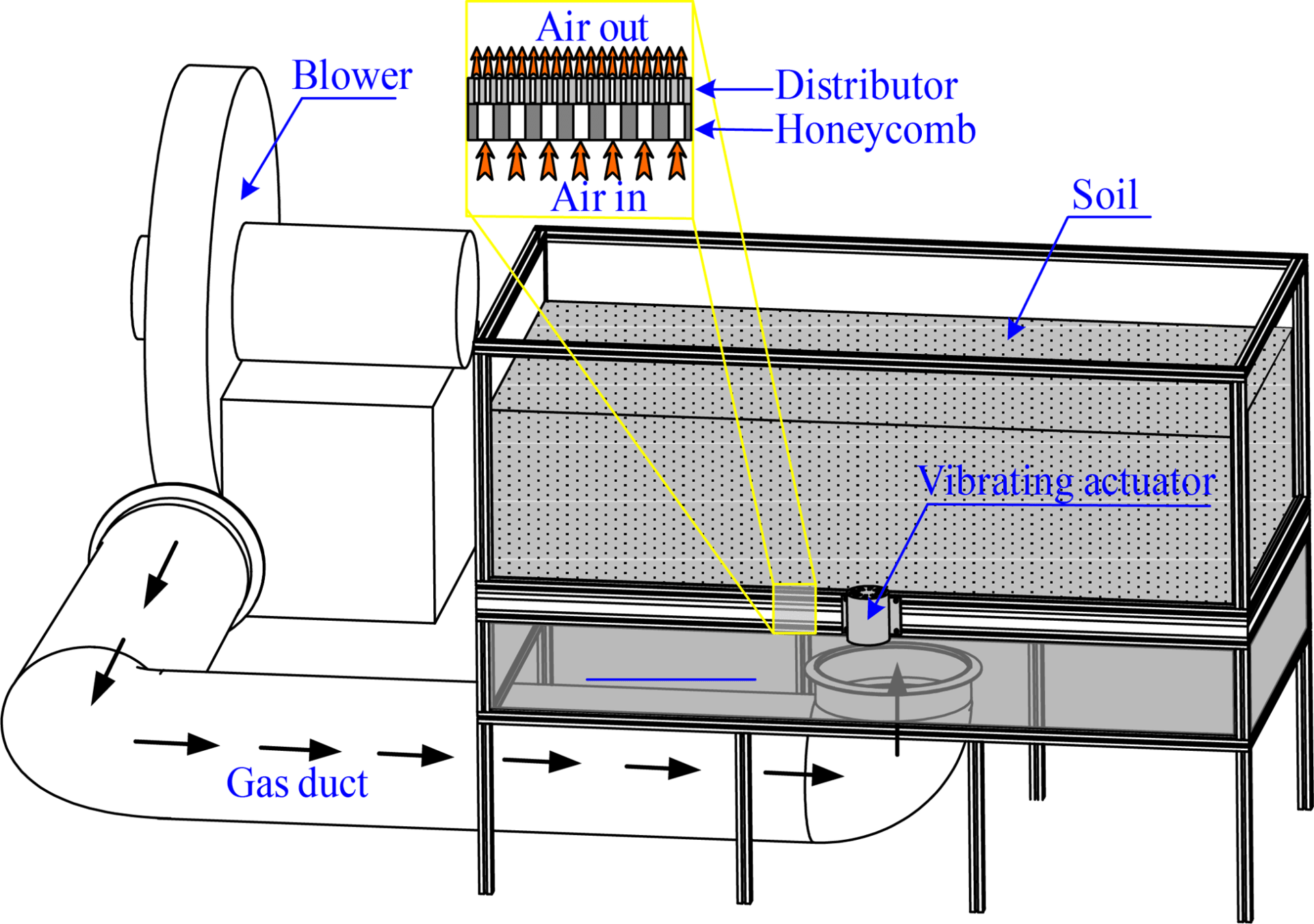

The Soil-Machine Interaction Laboratory (SMI Lab) at Northwestern University (Fig. 1) is designed specifically for the purposes of exploring the forces and deformation on objects and devices as they interact with soil. The centerpiece of the SMI Lab is a 6-axis robotic arm that allows for precise positioning and motion control of the object (Fig. 1b). The robot, an IRB 4400 manufactured by ABB, is equipped with a 6-axis load cell, as well as the hardware and software necessary for integrated force control, such that experiments can be conducted in either displacement- or force-controlled modes. The lab also features a fluidized bed that allows for rapid reconstitution of dry granular material at controlled densities (Fig. 1b and Figure 2).

Figure 1. (a) Soil-Machine Interaction Laboratory (SMI Lab) at Northwestern University just after installation in Summer 2017. (b) Robotic arm for 6-axis force measurement and integrated force control, shown positioned above the fluidized bed used for rapid reconstitution of dry granular materials.

Figure 2. Schematic of fluidized bed apparatus. Click HERE for additional details about the design, construction, and operation of the fluidized bed, and click HERE to watch a video of the bed in operation.

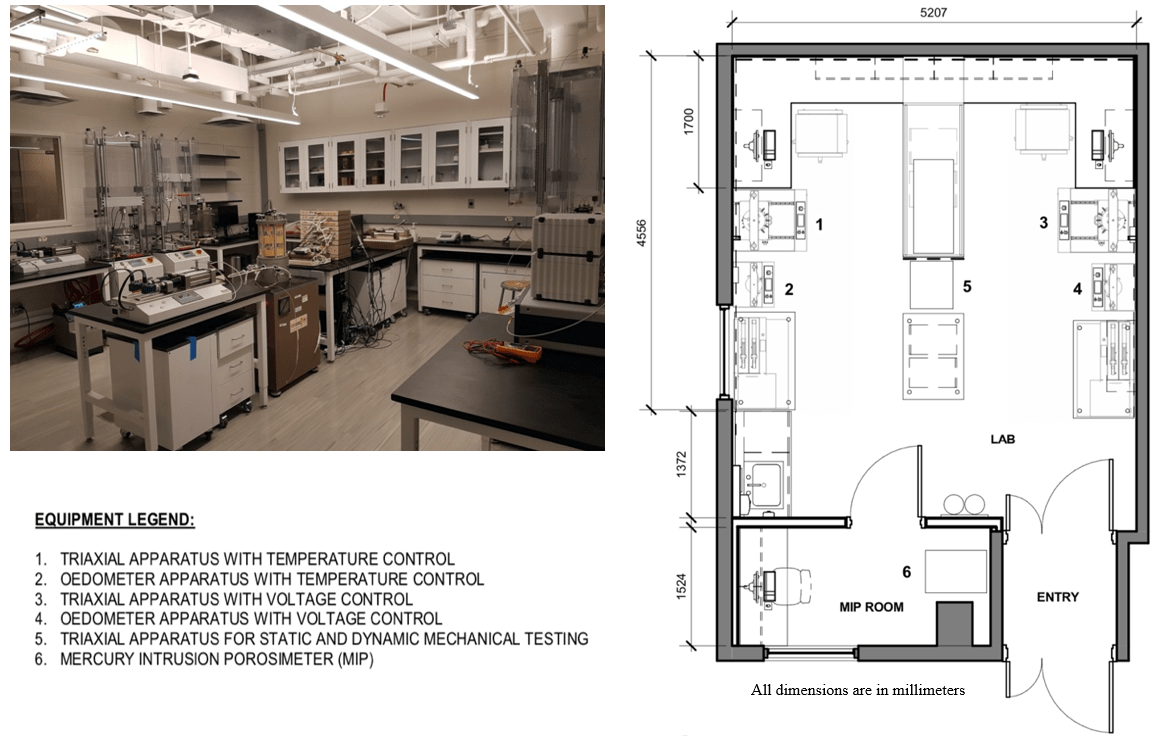

Mechanics and energy laboratory

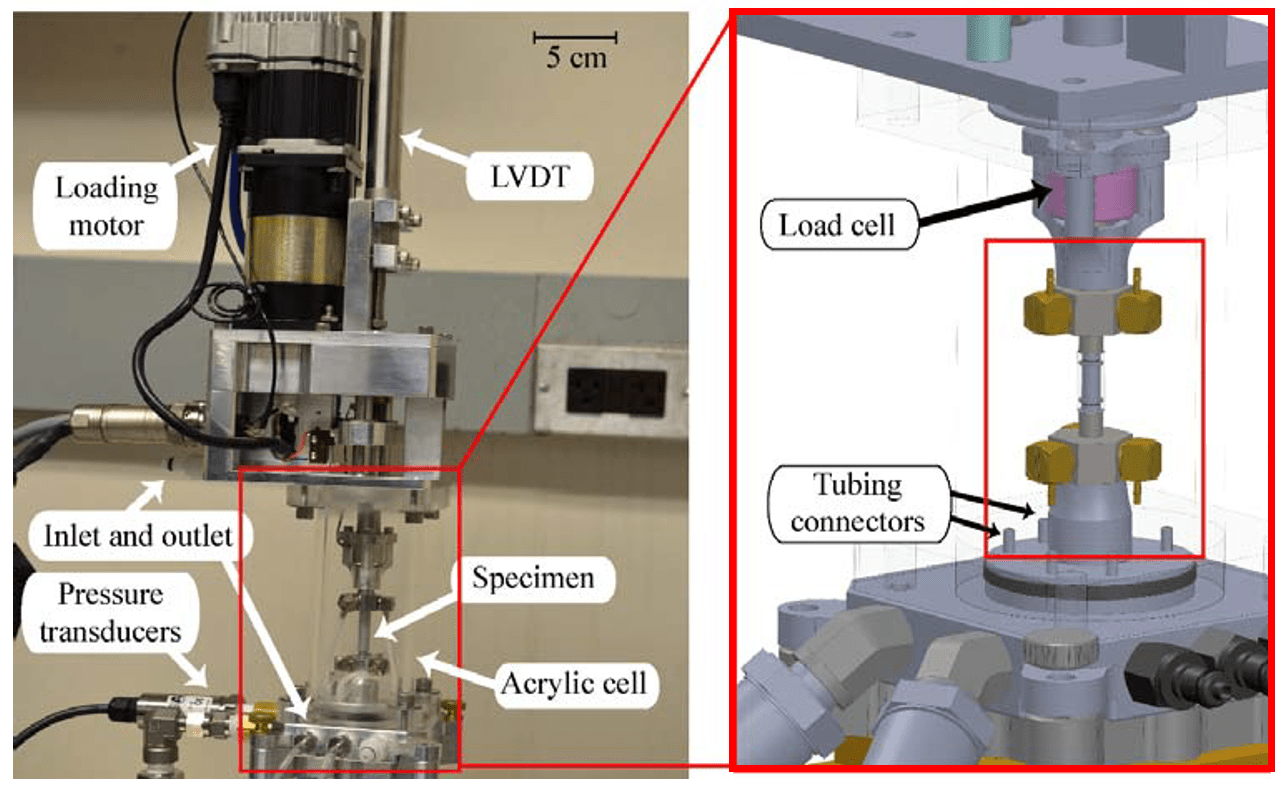

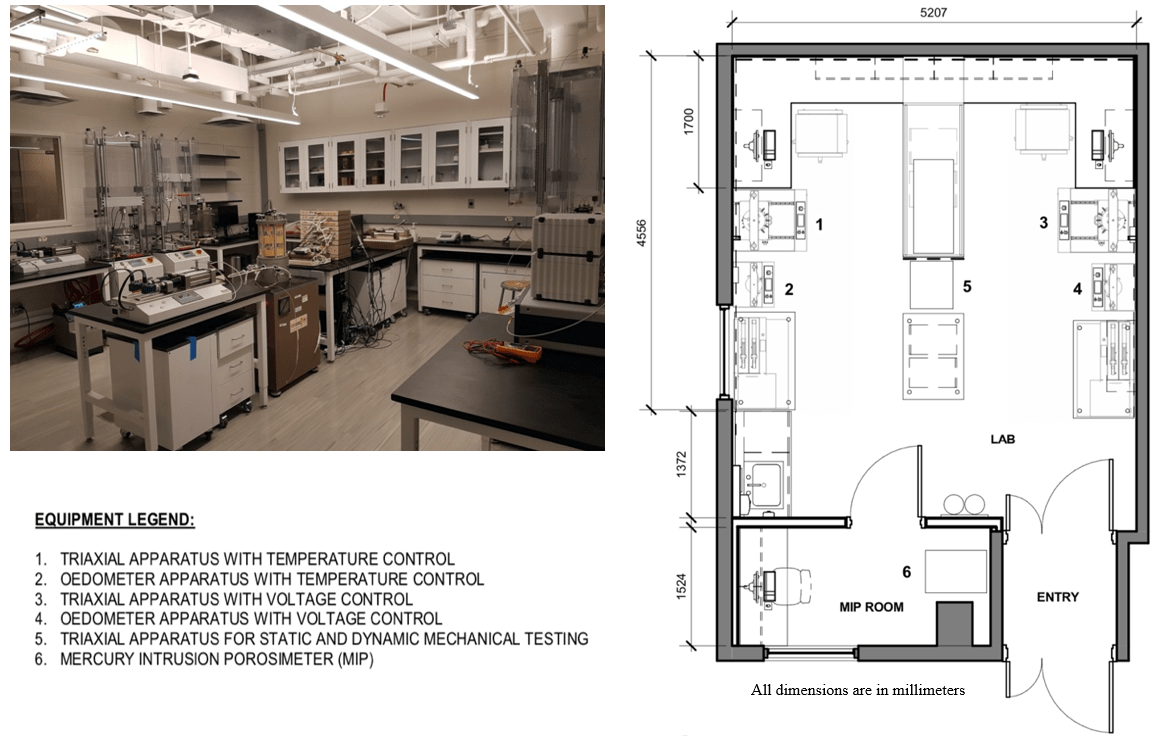

The Mechanics and Energy Laboratory (MEL) of Northwestern University has been designed specifically for the purposes of exploring the mechanics of geomaterials such as soils, soft rocks and concrete under the influence of multiphysical perturbations, including mechanical, thermal, electrical and chemical loads.

Various cutting-edge experimental apparatuses are available at the MEL. Together with conventional tools and apparatuses for the classification of soils, all of these apparatuses allow advanced investigations of the mechanics of geomaterials subjected to multiphysical perturbations:

• One triaxial apparatus and one oedometer apparatus with temperature control allow the creation of a broad range of cyclic and monotonic temperature variations and relatively high stress states to tested samples. These apparatuses allow to address advanced aspects of the thermo-hydro-mechanical behavior of geomaterials.

• One triaxial apparatus and one oedometer apparatus with voltage control allow for the creation of a broad range of cyclic and monotonic voltage variations and relatively high stress states to tested samples. These apparatuses allow to address advanced aspects of the electro-hydro-mechanical behavior of geomaterials, with information on thermal aspects as well.

• One triaxial apparatus for static and dynamic mechanical testing of material samples is available. This apparatus can test under high stress states material samples under isothermal conditions.

• A mercury intrusion porosimeter is also accessible in a dedicated room. This apparatus allows for the recording of information about the microstructure of porous materials.

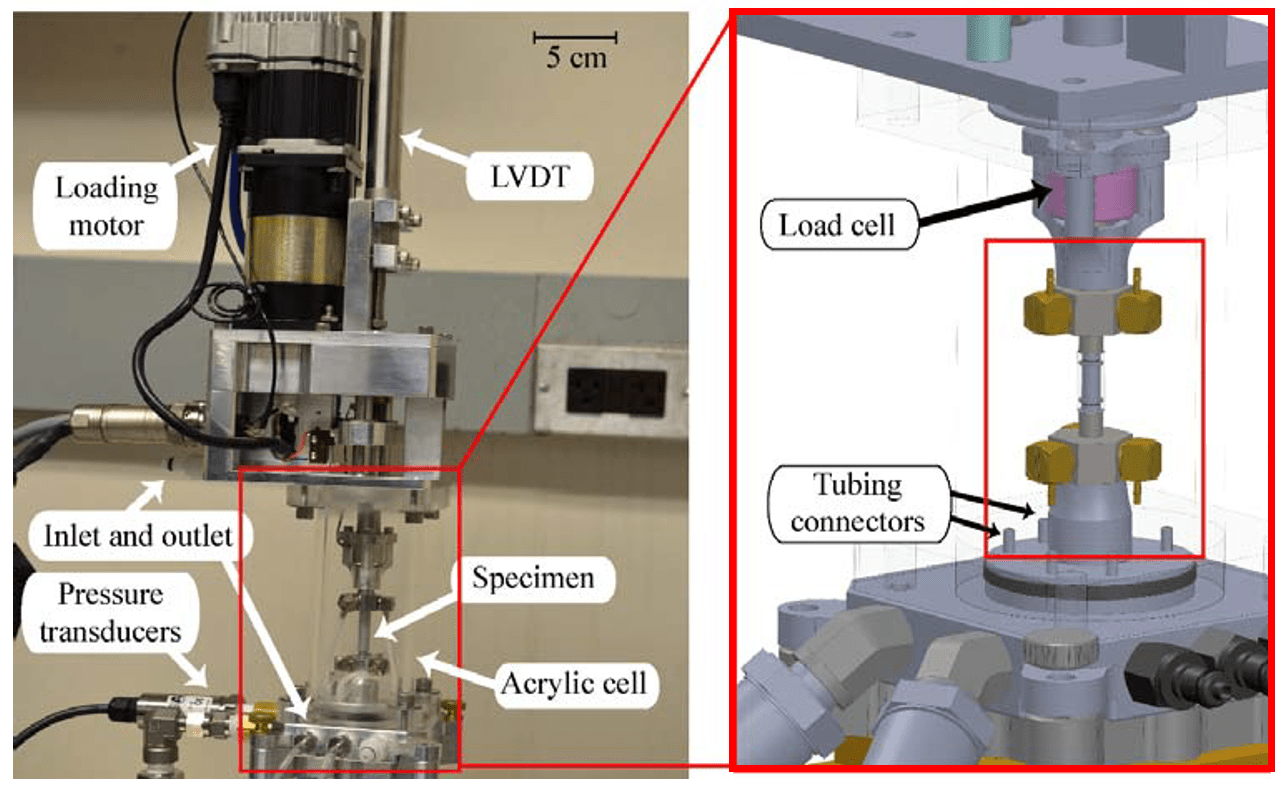

Modern testing techniques assisted by high-resolution imaging (e.g., 3D X-ray tomography) allow the quantitative observation of microstructure changes in materials subjected to mechanical and environmental loading. At the SPREE laboratories, we use these techniques to study the mechanics of variably saturated granular materials at high pressure. Such systems are tested through a custom-designed miniature loading apparatus allowing for a range of loading conditions, spanning from diametral compression in individual particles to comminution experiments in grain packing, saturation tests and reaction-transport processes. Such capabilities benefit from direct access to the Northwestern’s Synchrotron Research Center via the DND-CAT beamline located at Sector 5 of the Advanced Photon Source (APS), Argonne National Laboratory, as well as from the collaboration with scientists at the beamline 13-BM-D GeoSoilEnviroCARS (GSECARS) micro-tomography facility at APS, where in-situ mechanical tests can be run in conjunction with synchrotron X-ray microtomography (SMT). Such combination of testing and imaging capabilities enables researchers at the SPREE center to characterize in near real-time the evolution of the microstructure of granular materials at state-of-the-art spatiotemporal resolution.